Mining Solutions

Delivering value to the mining industry

A shutdown of any length of time can be detrimental on a mining site. Spencer recognizes how critical it is to keep your mining operations running 24/7. Our MHSA certified sales and services associates are right there with you making sure you have the fluid power parts you need to keep you moving.

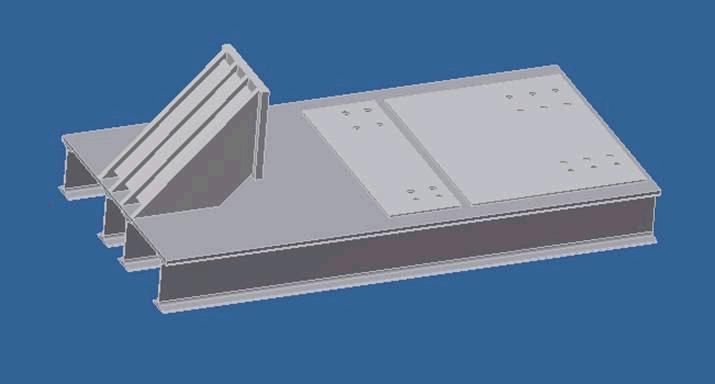

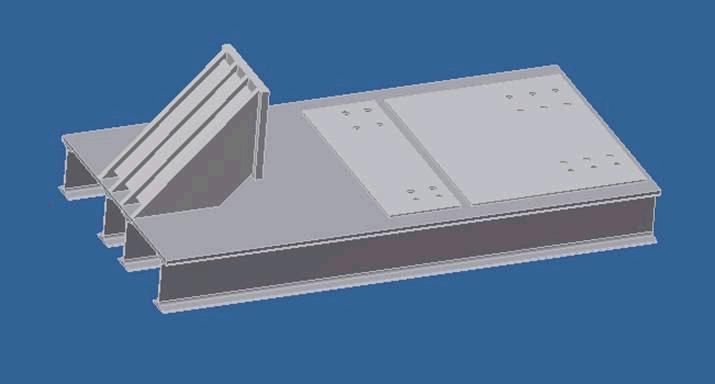

Komatsu 930E and 830 Suspension Cylinder Test Bench

Spencer Fluid Power designed a test bench for pressure testing of Komatsu 930E and 830 suspension cylinders utilizing Autodesk® Inventor® 3D modeling – enabling us to create a digital prototype of the final product. The bench was designed to test the cylinder seals in the high wear section of the cylinder rod. When it is installed on a loaded haul truck, the cylinder is positioned with the rod extended to the normal “riding position” of the cylinder. The cylinder has a 17” diameter piston, and the cylinder is charged with 1000 psi of nitrogen. This exerts 227,000 pounds of thrust on the stop plate of the bench. We designed the bench to handle the shear, bending and buckling stress.

Dragline door system delivers demonstrated accessibility

In the mining industry, dragline systems are used to help dig up coal and other material out of the ground. The draglines are a critical part of open pit coal mining as they are used to quickly remove the overburden – to expose the coal seam that is blasted. Shovels load the coal into haul trucks to transport coal to crushers and loadout facilities where it is loaded onto trains. When all the coal in the seam has been removed, the draglines are used to backfill the pit. The mine then uses aerial photos and elevation indexes taken by surveyors to reclaim the pit and return the landscape to its original state.

When a Spencer Fluid Power customer was looking for a hydraulic door system for their dragline, our team of engineers used Autodesk® Inventor® to design custom linkages, a model of the door, the cylinder and to demonstrate that the kinematics were correct. Now, when the draglines are in need of service, they have safe, easy access to the innards – whether it’s for changing ropes or generator/motor sets.